Automation can cause as many problems as it solves.

For automotive manufacturers or part suppliers, certain challenges are familiar: many from handling the vast amount of complex data that are part of daily production.

1. Understaffing or Lack of Qualified Talent

What it means

Your job is hard. Finding qualified people to do it is harder. Many manufacturers are familiar with challenges related to staffing, or trying to keep production running with workers who lack training and experience: standards slip, errors creep in, and deadlines are missed. Not to mention the fact that many teams are chronically understaffed due to budget issues. The result? You and your team have more tasks than ever before, and fewer people to do them.

Why it's important

When you’re working without a fully-staffed team, it becomes exponentially harder to do your own job—let alone the additional tasks that inevitably end up on your plate. Just keeping production running can be a challenge, let alone maintaining strict quality standards and constant improvement principles.

How to fix it

Unfortunately, short-staffing isn’t always something you can control. The key to working successfully in these conditions empowering yourself and your coworkers to do more with less. Embracing Kaizen principles or another quality framework can help staff feel like they have ownership and agency over their work, leading to better outcomes.

Alternatively, automating complicated processes or turning to digital tools instead of clunky outdated manual solutions can be the key you need to get things back on track, giving you time to focus on tasks that are truly worth your time.

2. Data Complexity

What it means

Gone are the days when putting a car together was a simple manual process. Modern automated production for something like a commercial vehicle can involve thousands of robots responsible for tens of thousands of individual process points, with each point having its own associated set of parameter data. Even smaller manufacturers such as component suppliers have complicated setups with a lot of critical data, while OEMs deal with compounded issues from variants and facelifts.

Why it's important

The complexity of robot programming data/parameters may be a pain point, but it exists for a reason: These data points, often only surfacing lines on massive spreadsheets, represent the real critical information like temperature of a weld, angle of a tool, or speed of a glue seam. Any mistake in just one of these items could have real, costly consequences. Even fixing errors that do crop up requires a deep understanding of parameter data—and doing so quickly requires that that information is available quickly.

How to fix it

Most manufacturers have some system in place for analyzing complex robotic joining process data. But these legacy tools might not be enough, especially as processing becomes more complicated and demands on your team increase. For example, having access to all spot welds’ XYZ position programming in a spreadsheet might not be good enough if base frames are bad and can’t be easily compared to nominal conditions. You should be constantly analyzing systems to make sure that your tools meet your needs—and seeking out new solutions if things aren’t working.

3. Ghost Spreadsheets

What it means

Keeping track of robot programming specifics is has historically been done with spreadsheets, and among manufacturers who haven’t found a better solution, this may still be the case. (add more) This creates “ghost spreadsheets”, or scenarios where staff are working from different spreadsheets created and last updated at different dates and containing different information.

Why it's important

It’s obvious why ghost spreadsheets can create serious manufacturing issues. For one, lacking a single source of truth means for current robot programming means that its hard to make good judgements or take actions based on accurate data. And when people disagree, coming to consensus is a time-consuming challenge; Even at its most benign, manual spreadsheet-based data distribution makes efficient communication impossible.

How to fix it

Make it a priority to keep all staff on the same page. A single source of truth for current robot programming is necessary to prevent ghost spreadsheets, which are the natural consequence of leaving staff to fend for themselves in accessing robotic joining process data.

While digitalization tools exist to automate the work of traceability in robotic programming, spreadsheets may be the best you can do. If so, aim to ensure that they are updated regularly to account for changes or touchups, and that everyone has access to the most recent data. If (like most manufacturers) you lack the time or manpower to devote to manual data processing task, then it’s time to consider digitalization tools that do the job for you.

4. KPI Constraints

What it means

COPQ, MTTR, MTBF: no matter what acronyms rule your factory, there’s no denying that it’s important to show that each of your choices is directed towards improving performance metrics. But putting that knowledge to work is complicated, especially as demands increase and systems become more complex. It can be hard enough to keep production lines running, let alone push the dial on something as massive as OEE.

Why it's important

While improving KPIs can be difficult, its undeniably important—no matter where in the factory you work. Constant improvement is a goal that all modern manufacturers are striving for, and performance metrics are the way it’s measured.

While it may seem like the complexities of your job are over-simplified when reduced by a manager statistics, the underlying principles of making more money spending less and creating safer products are the pillars on which successful companies—and products—are built. OEE, for example, represents the reality of how well quality, maintenance, and production teams are able to keep things running smoothly and efficiently.

How to fix it

Improving performance metrics often requires a “back-to-basics” approach: What are the biggest obstacles preventing you from improving, for example, availability or uptime? On closer examination, many manufacturers find that problems like scrap & rework have surprisingly simple solutions such as untracked programming changes. Tracing your organizational challenges to their root causes can reveal underlying issues like communications problems or data obscurity, which can be fixed with the proper tools.

It’s also important to be smart about what changes you do make: Rather than chasing ambiguous goals like ‘synergy’ or hopping onto the latest tech trends, any new system or tool you try should be evaluated based on real potential for ROI and the ability to solve challenges you’re familiar with.

5. Lack of Data Transparency

What it means

Whether you’re a weld analyst, quality engineer, maintenance professional, or wearing multiple hats, your job probably involves looking at robot programming data. The problem? That data is typically hard to access. Even trying to find something as simple as a process’s XYZ position takes up valuable time, and things like glue parameter can be impossible to access without stopping production entirely and stepping through a program manually.

Why it's important

In the best of conditions, accessing a piece of robot programming data may “only” take ten or fifteen minutes—but that doesn’t mean the problem can be ignored. The time adds up, especially when a specialist employee’s labor has to be diverted to the simple task of data retrieval multiple times per day. All manufacturing professionals know that time is money, and wasting either isn’t an option.

Worse still is the fact that some pieces of critical robotic joining process data go entirely unseen until problems arise. Tool orientation or path direction, for example, aren’t always viewable in spreadsheets of positions and parameters. Swapped IDs on a process introduced by bad programming won’t be noticed at all until a later change is made that results in faulty processing.

How to fix it

Oftentimes, the scope of this challenge is beyond what spreadsheets or new workflow policies can handle. Thankfully, tools exist to shine a light on obscure robotic processing data—while also automating the hard work of analyzing it.

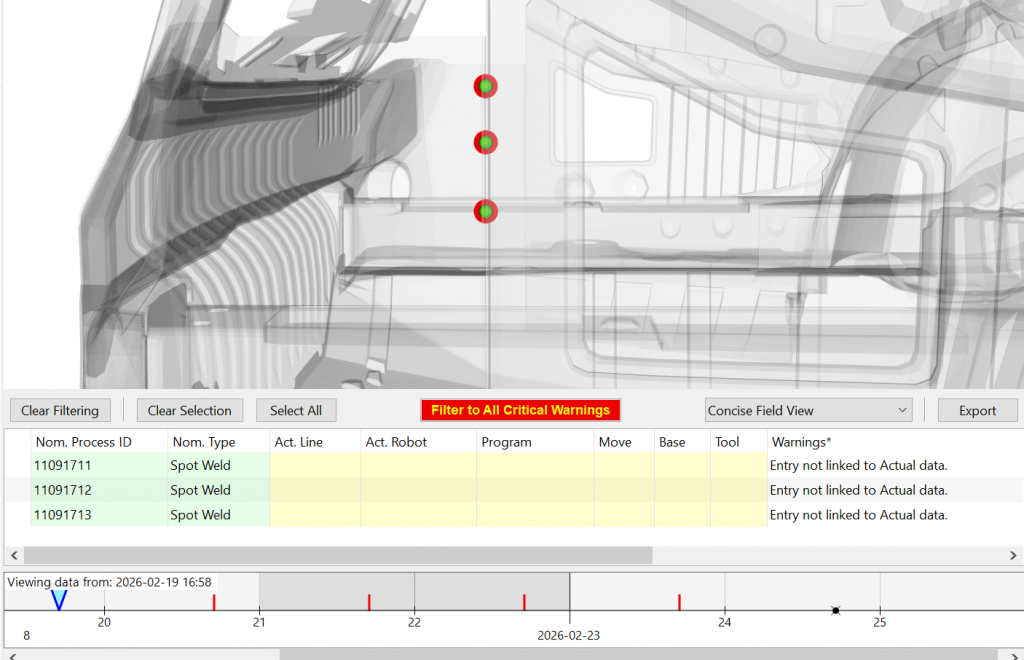

RoboLive® is the only solution available that provides a complete visual source of truth for all robotic joining process data, automatically updated and distributed to software clients that anyone can use. Using RoboLive®, accessing even the most complicated piece of data (such as weld timer data or glue parameters) is as simple as glancing at an intuitive visualization.

RoboLive® can’t solve all your problems in the workplace. But if you have challenges related to handling robotic joining process data, it can solve most of them.

RoboLive® extracts data from your production robots at regular intervals and makes it available to all staff in an easy-to-use client that documents any changes on a production timeline and analyzes new data for compliance with production standards.

If you want to find out why the world’s largest automotive manufacturer’s’ rely on RoboLive® as a production standard, reach out today. Free consultations are available.