DON'T JUST FIX PROBLEMS.

PREVENT THEM.

Your industrial robots produce a massive amount of data each day. Why not use it?

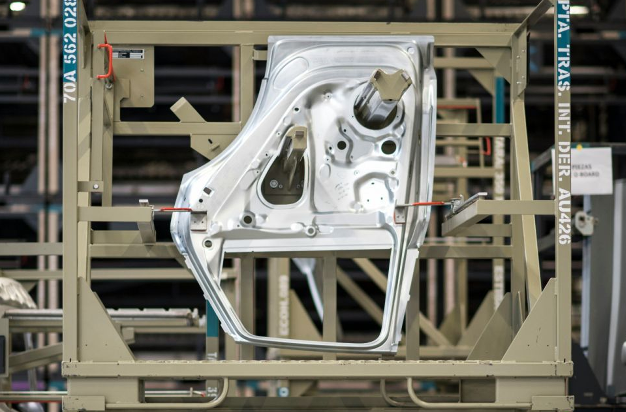

RoboLive® combines actual production data direct from processing robots, and integrates it with production plans and visual part models. The result? An always up-to-date report of your production state, and the tools to determine when production goes out of line.

-

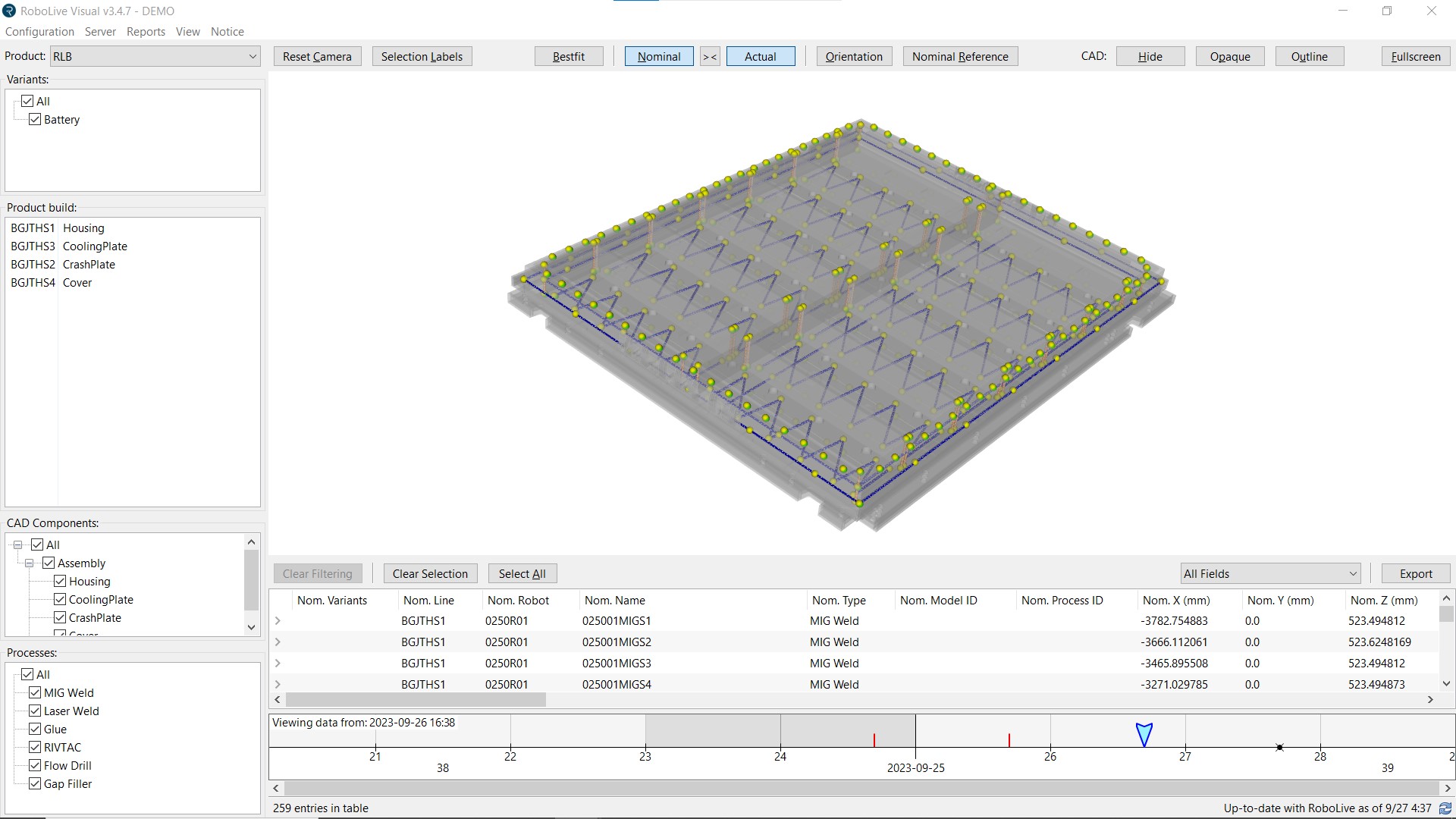

PRODUCTION TIMELINEGet a complete timeline of all robotic process data, visualized on models of the parts and products.

-

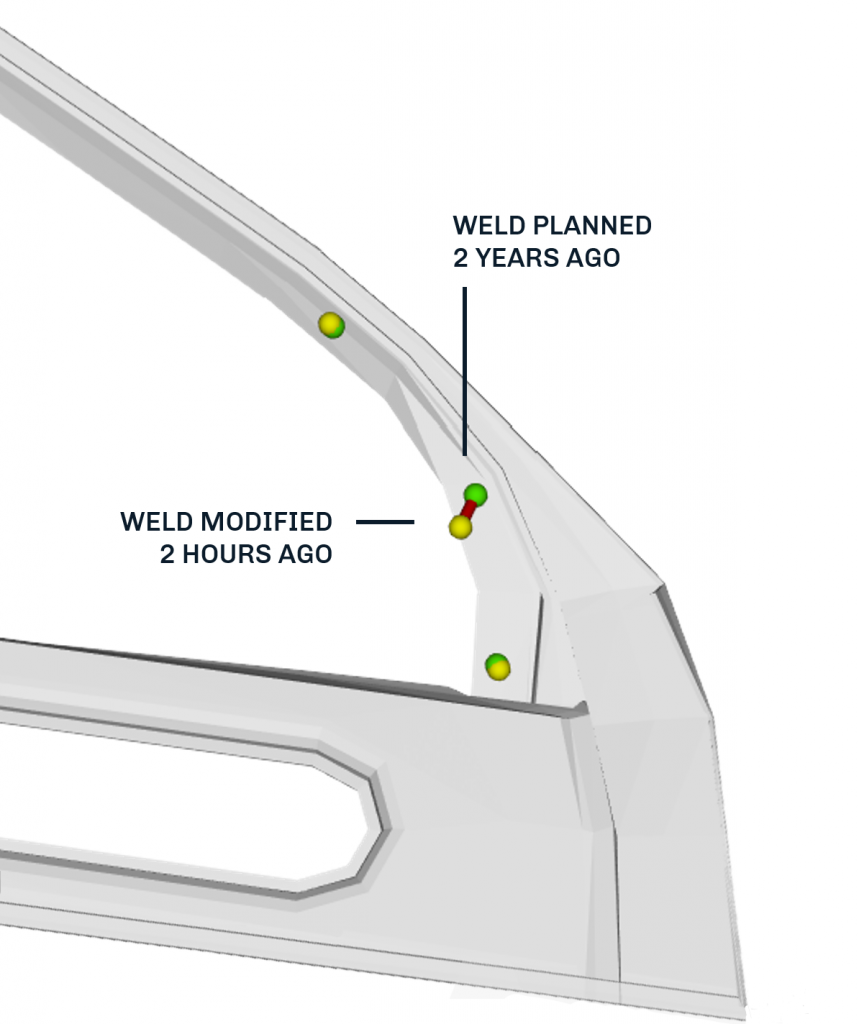

CHANGE TRACKINGSee every change made to your robot programs, every shift.

-

ANALYTICS AND REPORTSGenerate analytics, reports, documentation, and manuals in a single click .

A single tool for comprehensive data access:

The RoboLive® Visual Client is installable on any Windows PC, and combines your planned data, product models, and regular updates of real robot data into a simple visual format:

- A single source of truth for all robotic joining process data

- Real understanding of current programming

- Tracking all programming changes made

- Automatic error detection and analysis

RoboLive® Visual is used in daily production or in the integration of new products to facilitate any task that requires an understanding of current robot programming.

ideal & Actual data:

Parameters & Tool orientation

Programming errors

FOR ANY CHALLENGE IN THE BODY SHOP:

LESS DOWNTIME

The instant data access and single source of truth provided by RoboLive® reduces the amount of time needed to make repairs or adjustments during downtime.

REDUCE LABOR

Specific tasks like accessing weld controller data, checking glue parameters, or data analysis are greatly facilitated with RoboLive®.

LESS SCRAP

RoboLive® provides a report of all programming changes, meaning potential errors (a process missing, misplaced, or outside of specifications) can be detected near-instantly.

EASY TO INSTALL,

EASIER TO USE.

The RoboLive® Server is installed on the production network, where it receives production data from networked robots. The data is automatically analyzed and complied, and the results can be viewed on an installable client on any connected computer: from work-from-home laptops to line PCs.

Initial setup of RoboLive® requires almost no manual effort. Our team of engineers creates your custom installation with CAD and nominal data, installs the Server on a virtual machine, and your robots do the rest—forever.

ALL YOUR PRODUCTION DATA:

Filter by components,

joining types, and

process points.

See all process points,

nominal and actual, on

a model of each product

or part

Comparison of previous

plant states and tracking

of changes.

Detailed listing of all

processes and their

parameters.

Distribution of all

products via clients.

MADE BY THE BEST,

FOR THE BEST.

As a team of system integrators with over 50 years of experience in the field, we know exactly what problems you’re facing. We’re ready to help you harness the power of Industry 4.0 and tackle modern manufacturing challenges like the pros.

RoboLive® is running right now on thousands of robots in production lines around the world: Read our case studies and client testimonials to find out why some of the biggest names in manufacturing rely on RoboLive® every day. Then get in touch with our team and join them.