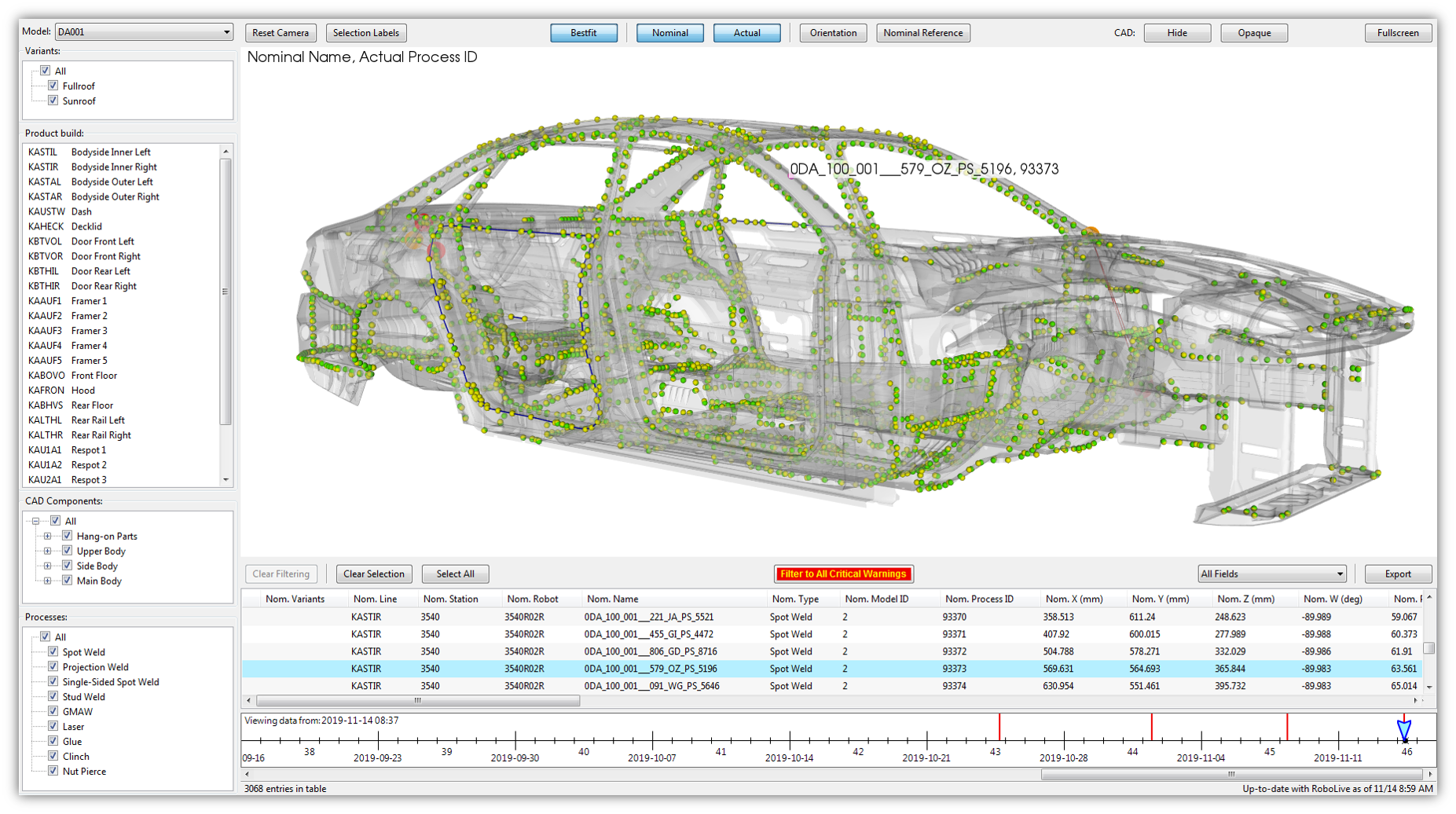

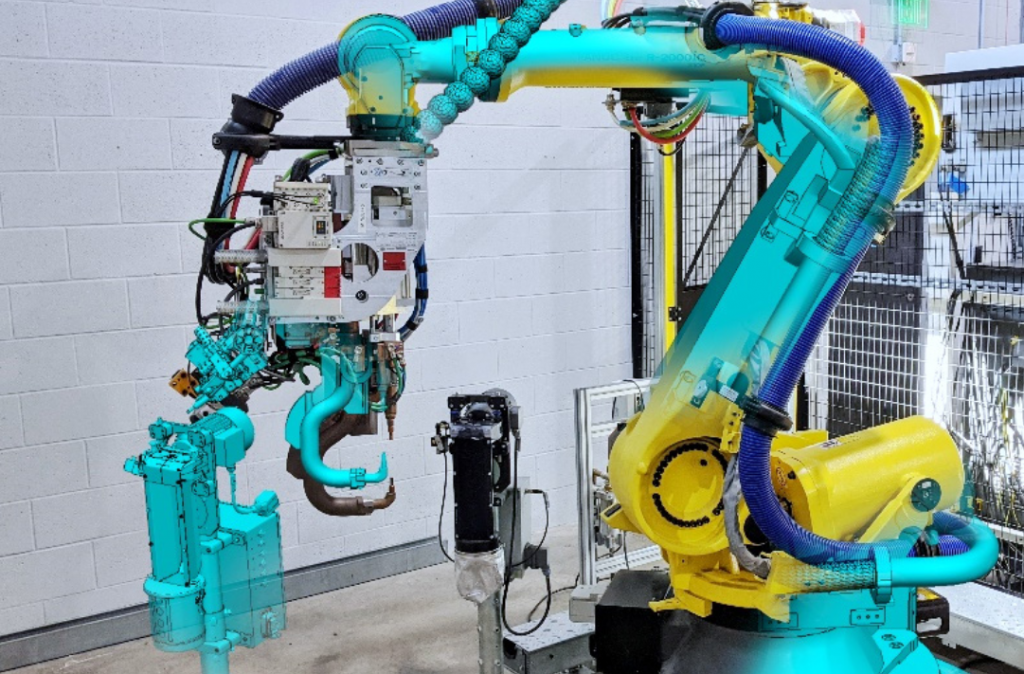

1. STARTING STATE

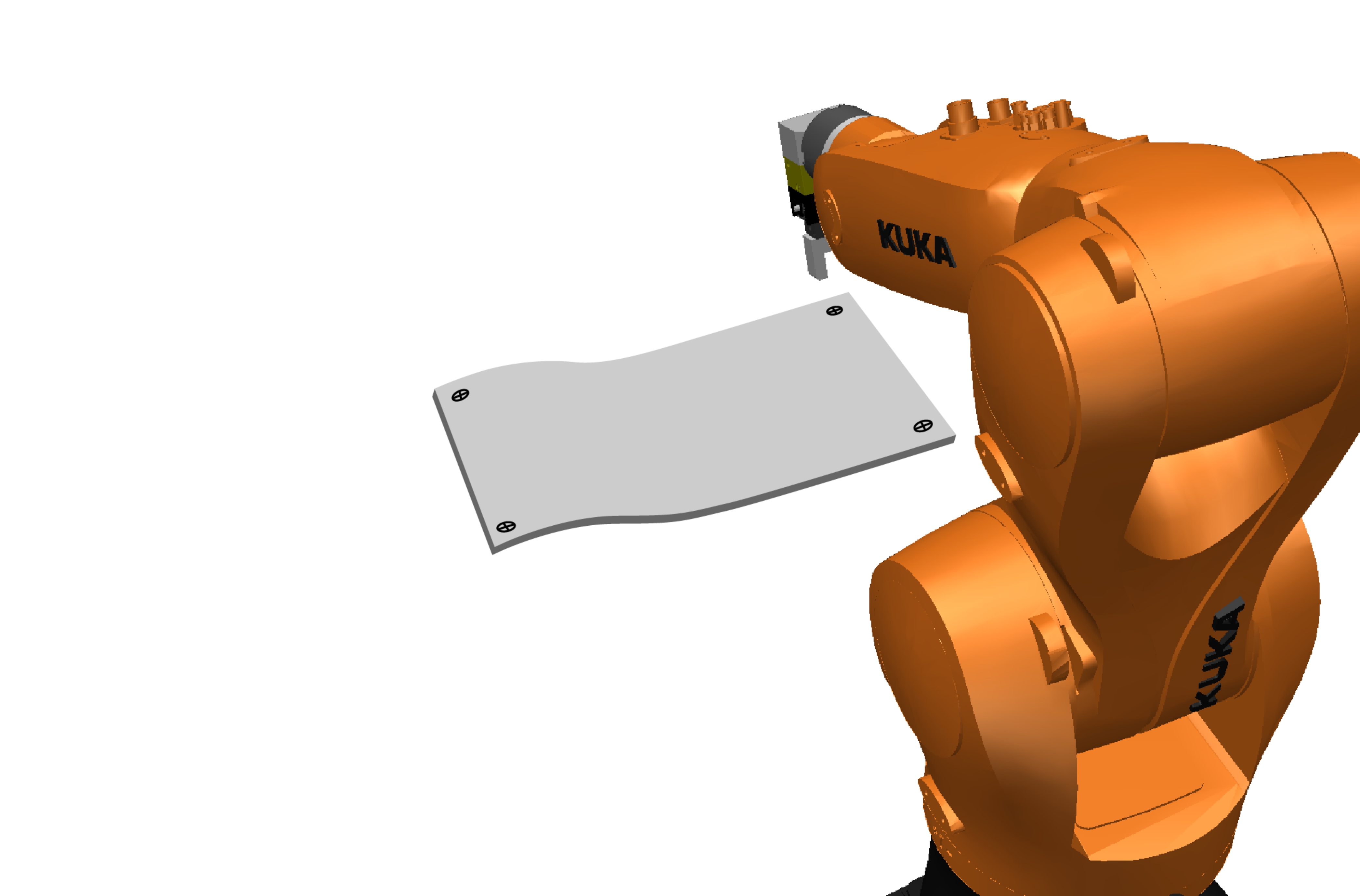

2. SIMULATION

3. PROGRAMMING

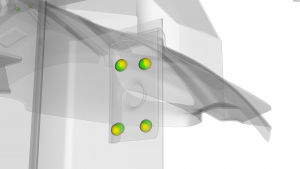

4. CALIBRATION

5. FINAL RESULT

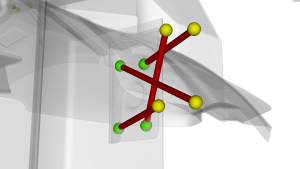

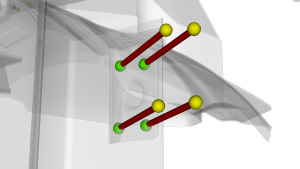

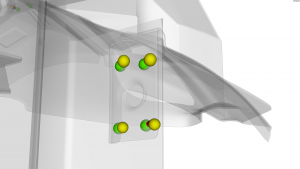

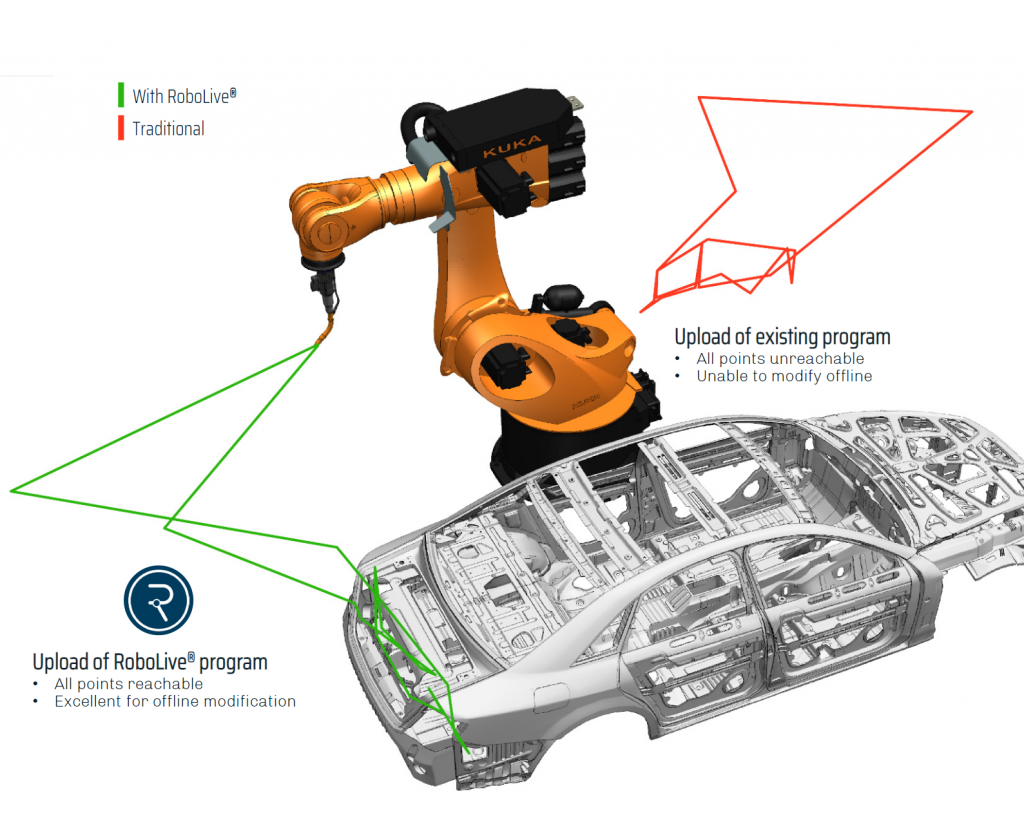

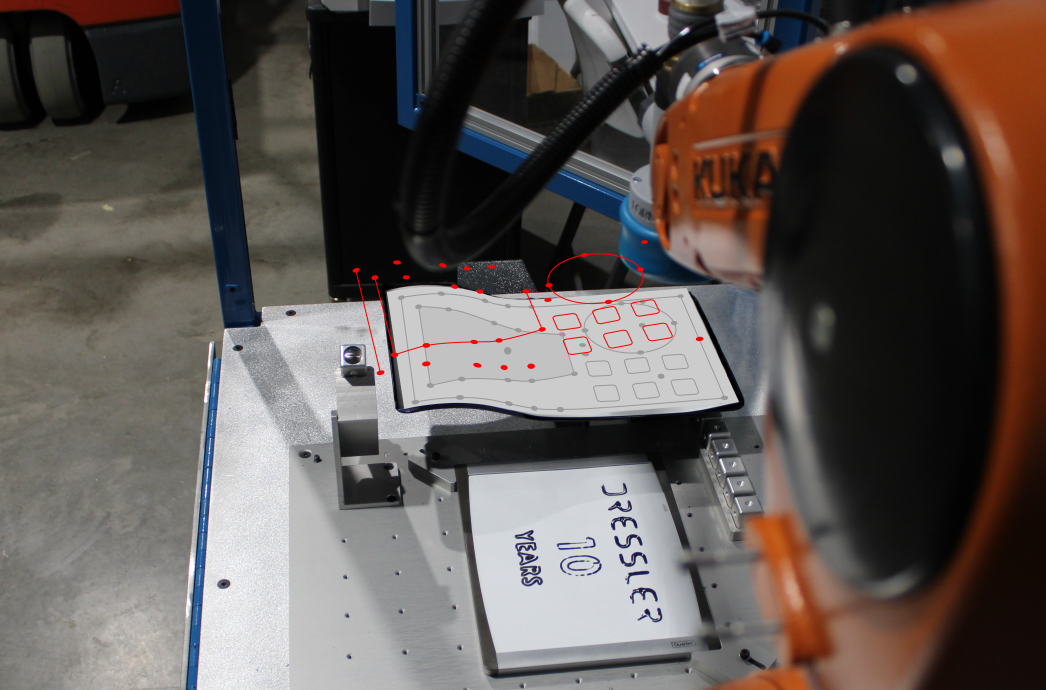

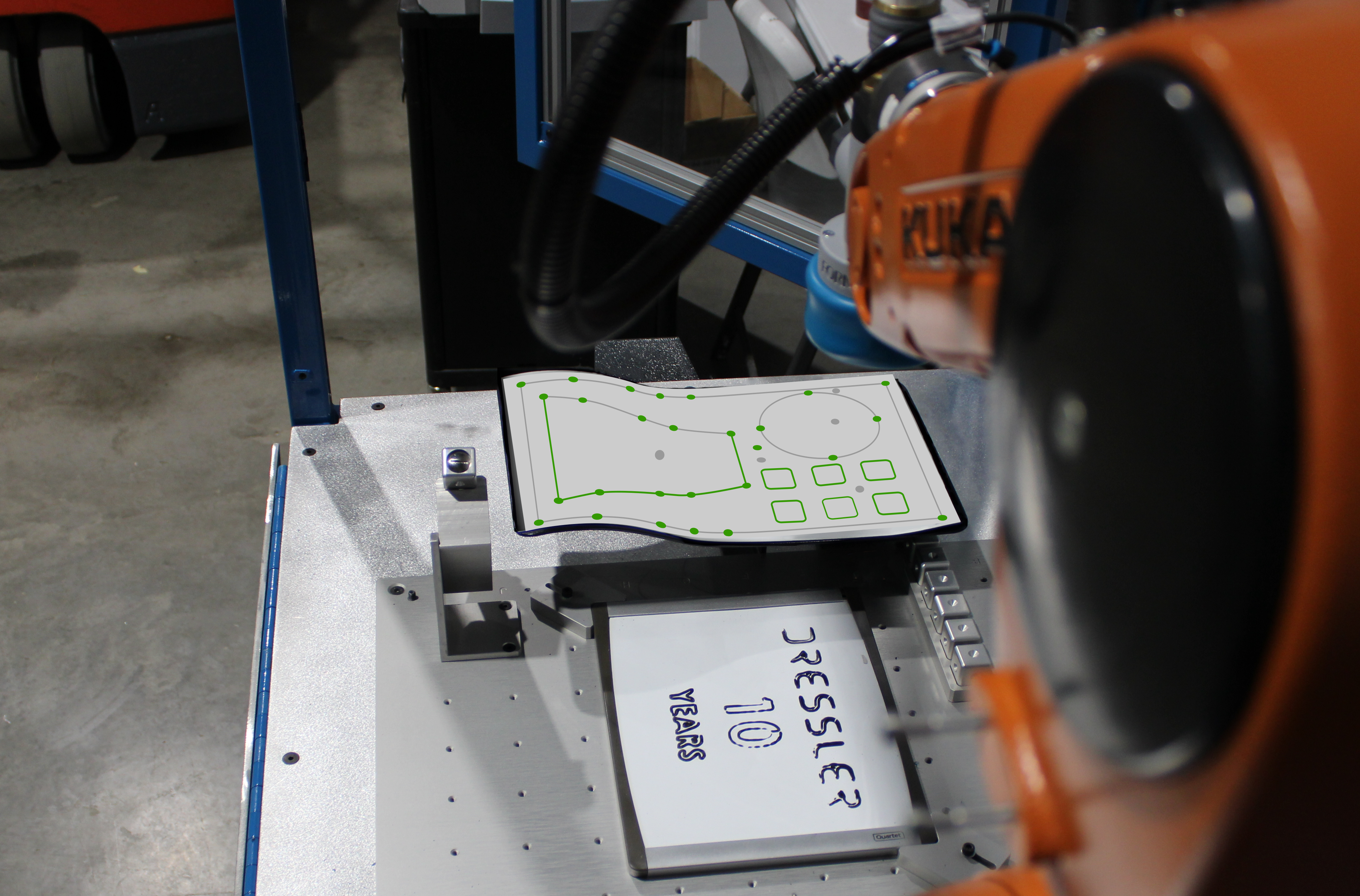

PATH CALIBRATION

Application of simulated paths in commissioning can be a challenge: real factory conditions differ from virtual environments, so virtually commissioned programs may not line up properly or function as expected. The solution, manual reteaching, is a costly and time-consuming workaround.

RoboLive® offers a new way to make use of your simulations, letting your technicians adapt virtual robot paths to on-site conditions automatically.

RoboLive®’s Path Calibration tool takes the data of a robot program (process points as well as frame data) and compares it to calibration points in both the physical and simulated factory environment. The software then calculates the best possible overlay of the calibration points, adapting the program to real conditions with minimal need for manual adjustment.