GET THE FULL STORY.

ROBOLIVE® AT A GLANCE:

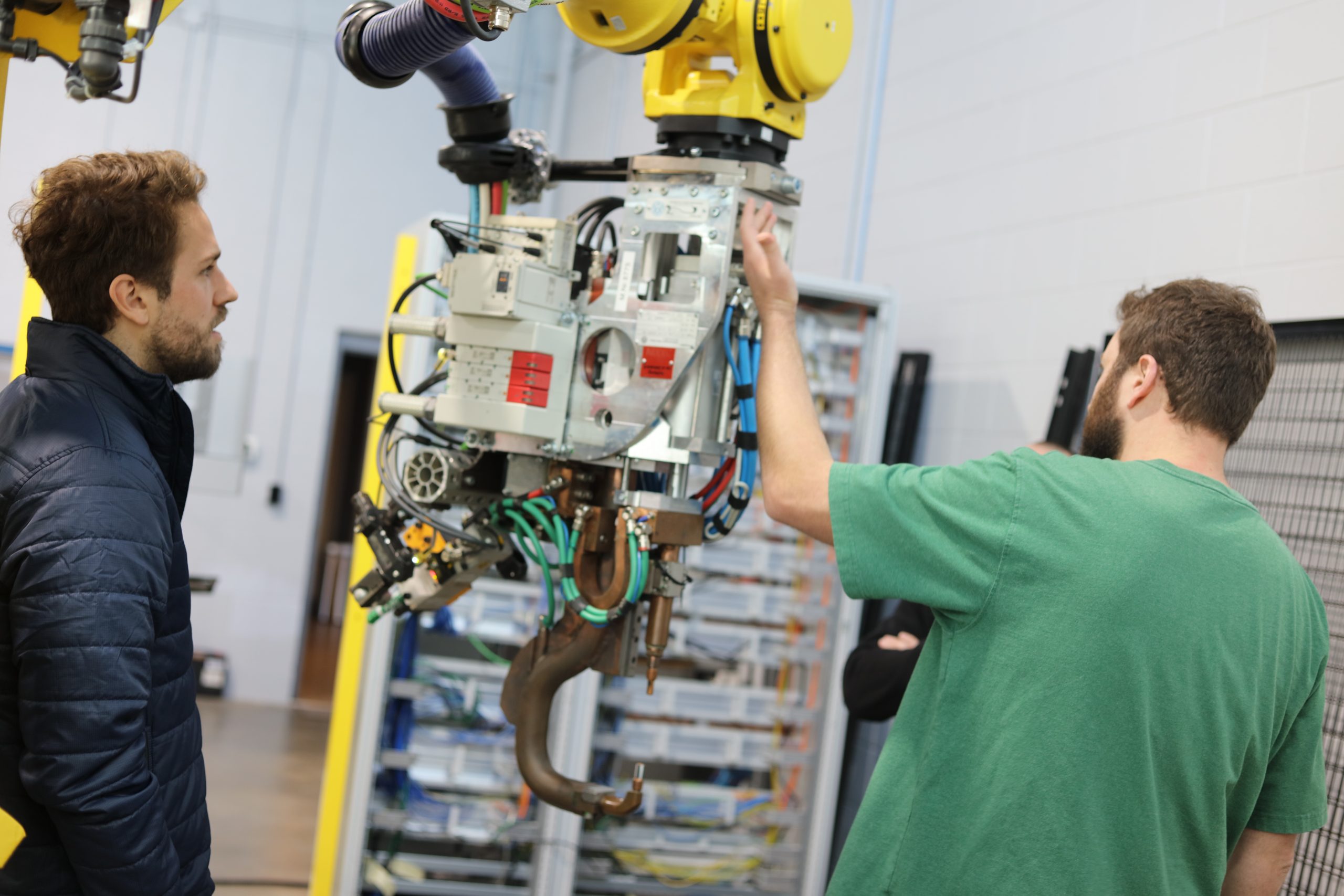

Through a unique and comprehensive set of analysis tools, RoboLive® lets manufacturers and system integrators visualize robotic processes and identify production problems before they occur, all in a one-stop software solution.

RoboLive® addresses the most common challenges facing manufacturers today, and the results are measurable. By preventing recalls, reducing scrap, and minimizing downtime, users save time & money, and see improved production quality immediately.

RoboLive® is composed of 5 main elements:

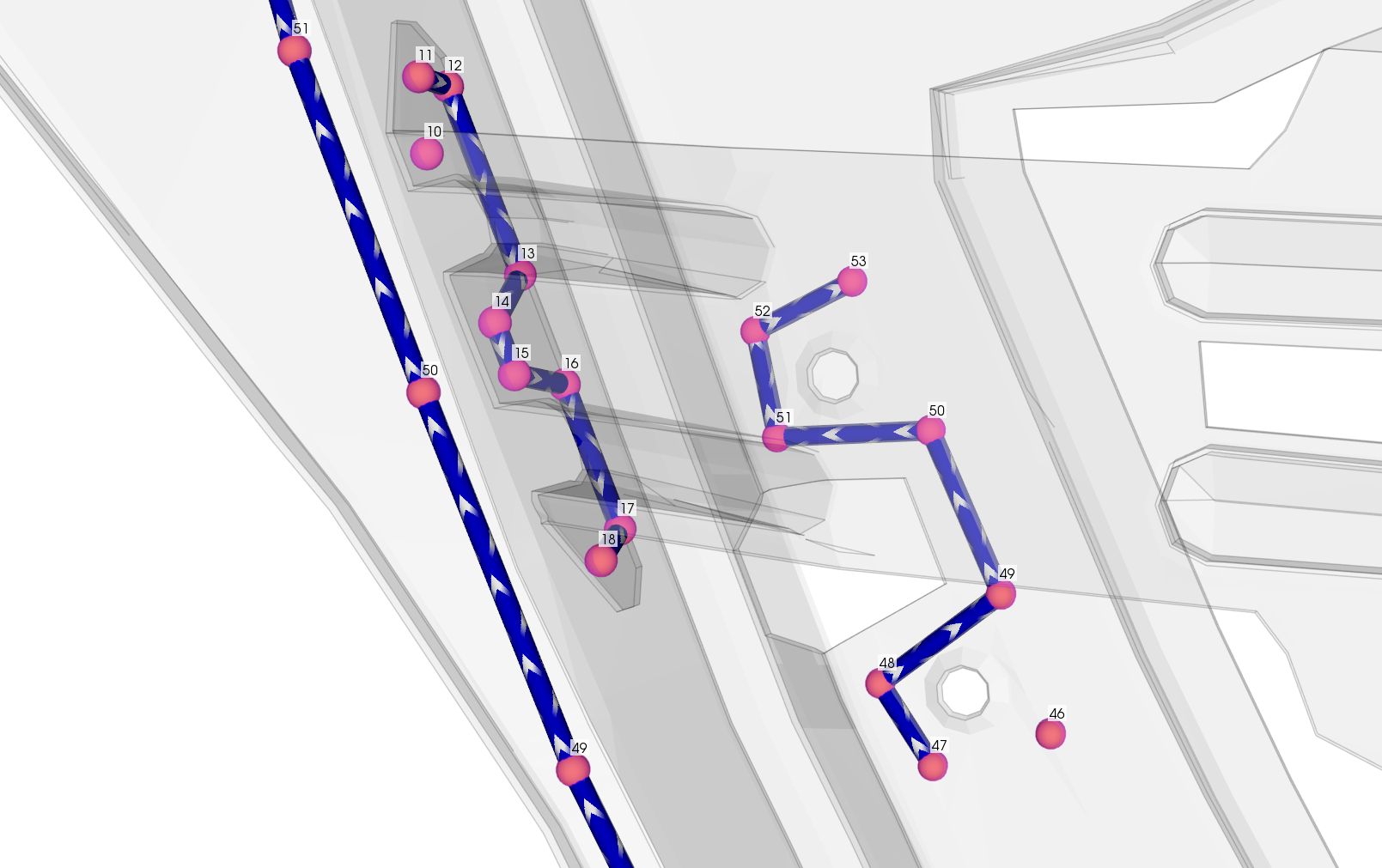

- Process Visualization displays process paths and data points on a 3D visualization of the part.

- Path Calibration adapts theoretical robot paths to real-world conditions seamlessly.

- Vehicle-0 Determination determines a vehicle’s origin point in real space without the need for laser measurement.

- Software Overview summarizes robot-specific information into a single, accessible document.

- Robot Documentation creates technical manuals for each of your robots automatically.

THE ROAD SO FAR:

Since the project began in 2020, the RoboLive® team has been dedicated to developing and refining our software solutions:

the START OF AN IDEA

SUCCESFULLY DEPLOYED

RoboLive's first EXHIBITION

IZB Top 20 Innovative Product

IN THE NEWS:

The software has the potential to have a radical impact on robotic manufacturing processes. My drive is to leverage this potential and to bring the great benefits of RoboLive® to our customers.”

– Heiner Steinbrink, Operating Manager

CONTACT US:

EUROPE:

Arne Brökers

Account Manager

a.broekers@dautomation.com

+49 (5332) 9306-0

NORTH AMERICA:

Chloe Grimes

Communications Manager

c.grimes@dautomation.com

+1 (423) 509-0268