MEET ROBOLIVE FOR SYSTEM INTEGRATORS.

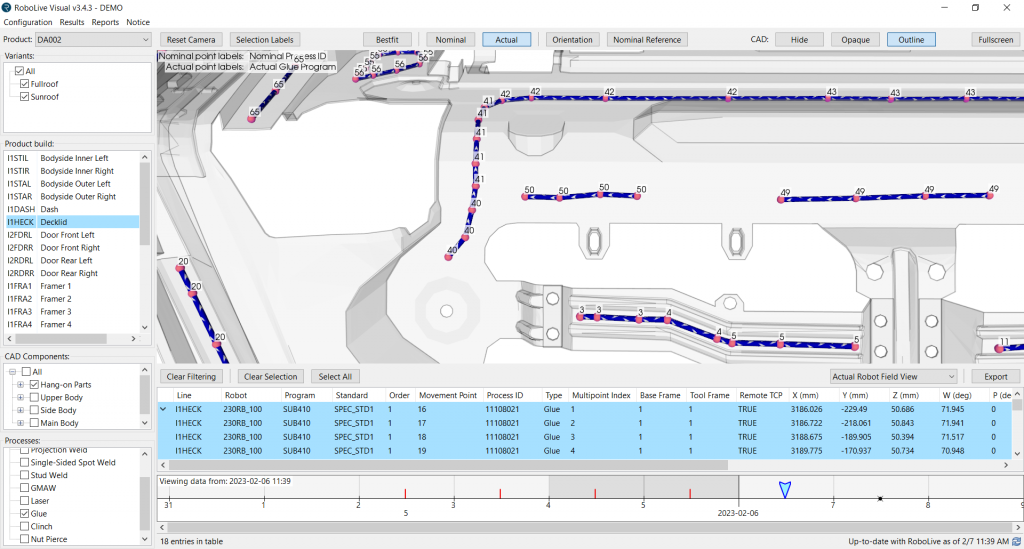

RoboLive®’s dynamic tools offer new opportunities for plant commissioning and optimization.

TACKLE THE TOUGHEST COMISSIONING CHALLENGES WITH EASE.

Modern system integrators face new challenges every day. While developments in automation continues to transform the face of manufacturing, associated challenges are developing for technicians.

More robots means more data—and with the difficulty of manual analysis, the associated information isn’t always close at hand. That’s not all: tight schedules, late information and changes to the plant increase time pressure, while subcontracting and freelance programmers can produce qualitatively different results and questions of responsibility.

These challenges add up. Missed quality benchmarks, budget overruns, and delayed results are all possible outcomes when you’re unequipped to meet the challenges posed by Factory 4.0.

DIGITAL TWIN NOT USABLE?

Problems add up when simulations are inaccurate or differ from real plant conditions: Offline programs often can’t be used properly, programs are rewritten on-site, and hard work goes to waste.

DEPENDENT ON EXPERTS?

The operations in a complex production plant are hard to understand, even for experienced techs.

Observational tools at the control level can help, but without visual help at the robot level, knowledge is localized to specific personnel.

NO TIME FOR OPTIMIZATION?

Many optimization ideas are not implemented: downtimes windows production are short and changes to quality-relevant processes are risky.

WORK SMARTER, NOT HARDER.

RoboLive® works for system integrators throughout the entire commissioning process.

Traditionally time intensive and expensive processes like base frame determination or application of virtually commissioned paths are made easier with RoboLive®‘s advanced suite of tools, and standards compliance is ensured through automatically generated documentation and overviews.

SAVINGS YOU CAN COUNT ON.

RoboLive® shifts the work of commissioning to the planning phase, so that later phases of work are less time and effort intensive. It’s designed to do the heavy lifting at the hardest parts of the commissioning process, making application of offline programs and refinement faster and easier than ever before.

With extensive documentation, analysis, and visualization tools, you’ll be able to produce higher quality work effortlessly—in some cases, reducing personnel needs by up to 50%. RoboLive® compiles project data like technical manuals and archives into an easy-to-read single source, meaning your critical information is always close at hand.

The result? Standards compliant, on-time results that don’t need any further revision.

Projections are based on the following assumptions: 10 lines at 3,000 commissioning hours per line; 300 programming corrections at 1 hour per correction. $50 per hour average wage.

TRY IT FOR YOURSELF:

DEVELOPED FROM OUR OWN EXPERIENCE:

RoboLive® was developed by a team of engineers from Dressler Automation, a system integration and electrical engineering firm with over 50 years of international expertise.

Originally a solution developed for our own internal use, RoboLive®’s tools are specifically designed to counter the challenges we know modern system integrators are facing.