If you’re a tech-forward manufacturing professional working with industrial robots, you probably already know what RoboLive® can do for you. Whether you’re a manufacturer or system integrator, a plant manager or a robot programmer, RoboLive® offers tools and insights that help you take control of your industrial robots. But here’s something you might not know: These features combat the exact issues manufacturing automation pros face, because they were developed from years of manufacturing automation experience.

RoboLive® was created by a team of engineers from Dressler Automation, an international leader in electrical engineering for automotive manufacturers. Founded over 50 years ago in Germany, Dressler Automation began in the then-developing field of early robotics and electronic boxes. Over the years, the firm’s reputation and client base spread, with a team setting up the company’s first US office in the vibrant automotive manufacturing hub of Chattanooga, Tennessee. Automotive manufacturers and their suppliers are well established in the area, with the largest producing over 250,000 vehicles annually.

Dressler Automation’s Chattanooga team tackled big projects in commissioning and industrial maintenance but the rising tide of Factory 4.0 began to pose new challenges that the manufacturing industry was unprepared to face. How do staff keep track of the massive amounts of production data generated each day? When a bad part is produced, how can engineers quickly determine where and when the error occurred? Visualization tools exist for other parts of the factory, but what about programming data like weld or glue parameters? These are all challenges that the RoboLive® software now addresses—but at the time, no such solution existed. It was up to Dressler Automation to invent the next phase of the robotic revolution.

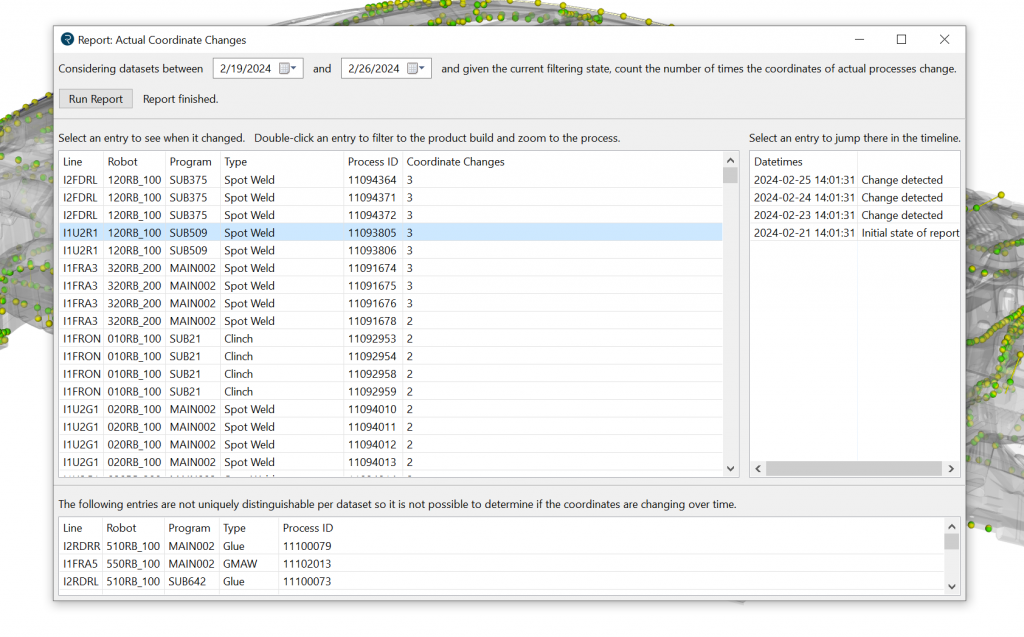

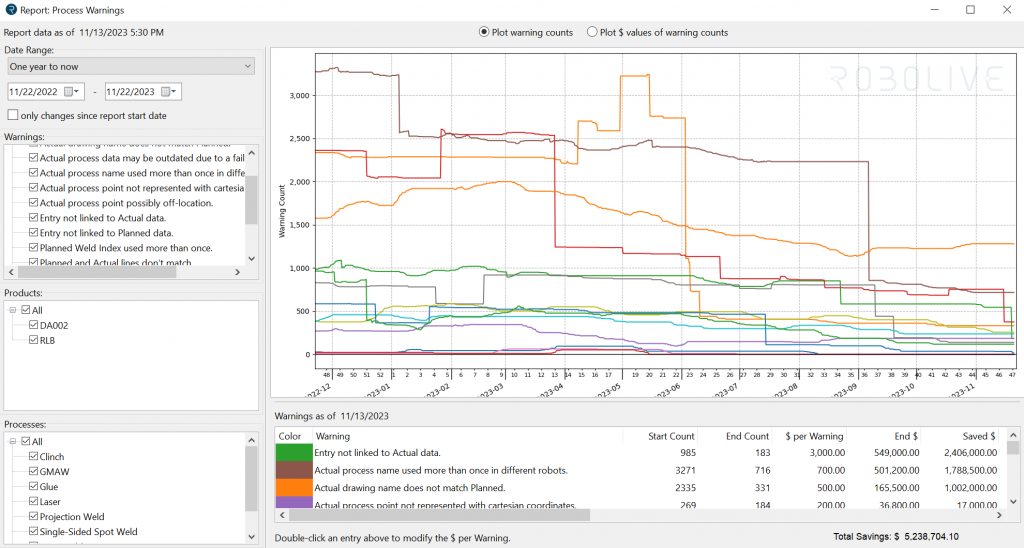

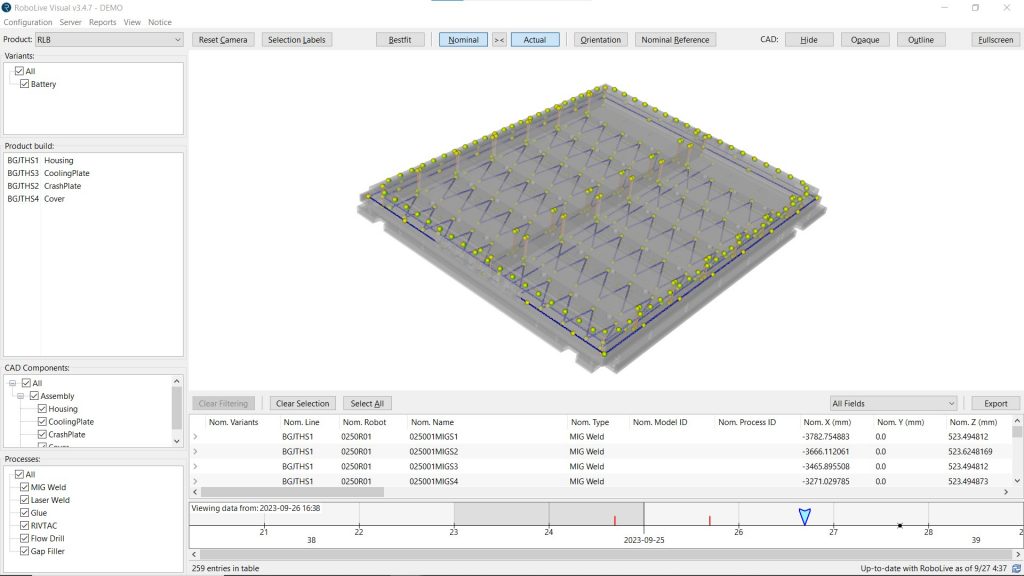

RoboLive® combines several key features—path calibration, base frame correction, documentation, and more—around a base of process visualization to give you the most complete look into your robotic production lines possible. The software automatically retrieves actual process data from your robots at regular intervals and displays it alongside planned instructions and part CAD models. Code rules, specifications, and specific standards are factored in, meaning you can see any issues or deviations instantly. A robust set of analysis tools and custom warnings provide a clear look into errors and information that otherwise would be impossible to visualize.

RoboLive® was originally developed and deployed on the factory lines in Chattanooga, and that’s where we first proved the software’s value. With all production information viewable in 3D at a glance, downtimes decreased and specialized personnel were no longer necessary for understanding data. RoboLive® allowed staff to identify and correct issues before bad parts were produced, leading to a reduction in scrap costs and decreased potential for recall.

The function of a completely new solution like RoboLive® was clear immediately—as was the need to share it with other manufacturers. The dedicated RoboLive® software team at Dressler Automation was created and began to refine the software into a versatile toolkit for maintenance managers, QA, and plant management alike. Working with manufacturers from a variety of industries and countries, RoboLive® has become a critical part of the production process at some of the largest plants in the world.

Whatever manufacturing challenges you’re facing—complex variants, unique processes, or specific standards—RoboLive® offers a solution. Our software is custom tailored to each facility’s needs, and we develop lasting relationships with our clients to ensure you’re making the most of your industrial robots. Reach out today for a free custom consultation, or submit a contact form for information on how to request a trial or pilot project.