Every part on a car must be handled with careful attention to quality, but EV batteries may be one of the most delicate components. As the literal ‘heart’ of the rapidly growing electric vehicle market, batteries demand particular attention in the manufacturing processes. For example, even a tiny leak that lets in water would completely compromise the part, leading to disastrous defects.

For that reason, it’s important keep a close eye on any possible changes to the production process. As with the body, batteries are largely assembled by robotic arms in a long and complex series of operations. It’s often more data than any one person can keep track of, which is where software solutions like RoboLive® come in.

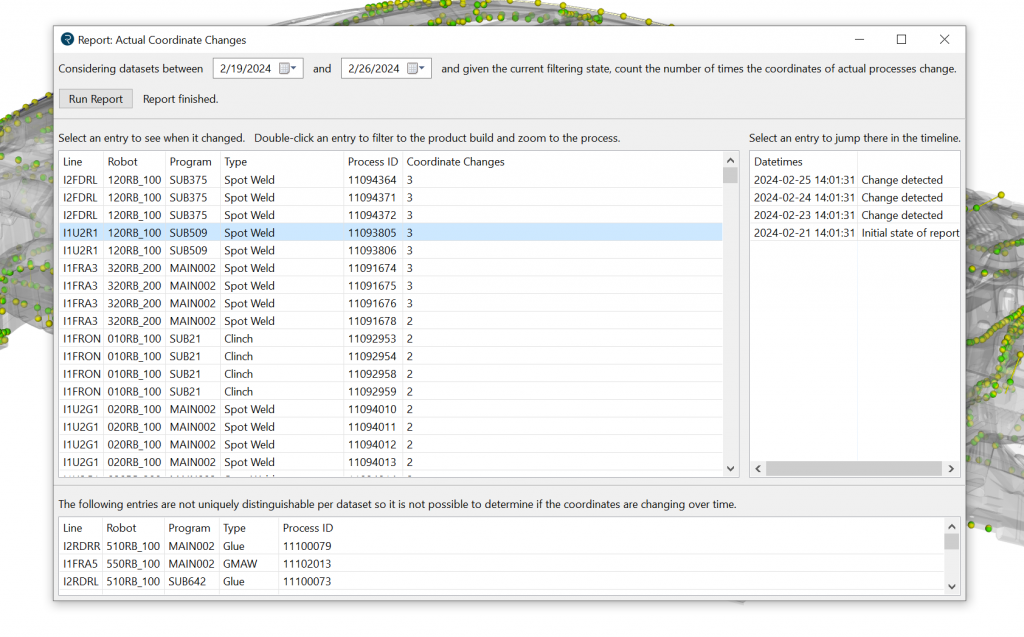

RoboLive® is well established as a tool for automotive manufacturers, but it’s capable of so much more: Battery manufacturers in particular see benefits from features like the change tracking and timeline history. RoboLive®’s timeline gives you a complete overview of every change made to your robot programs, as often as shift to shift. That means you’ll stay on top of any potential issues on your production lines, and can solve them faster than ever.

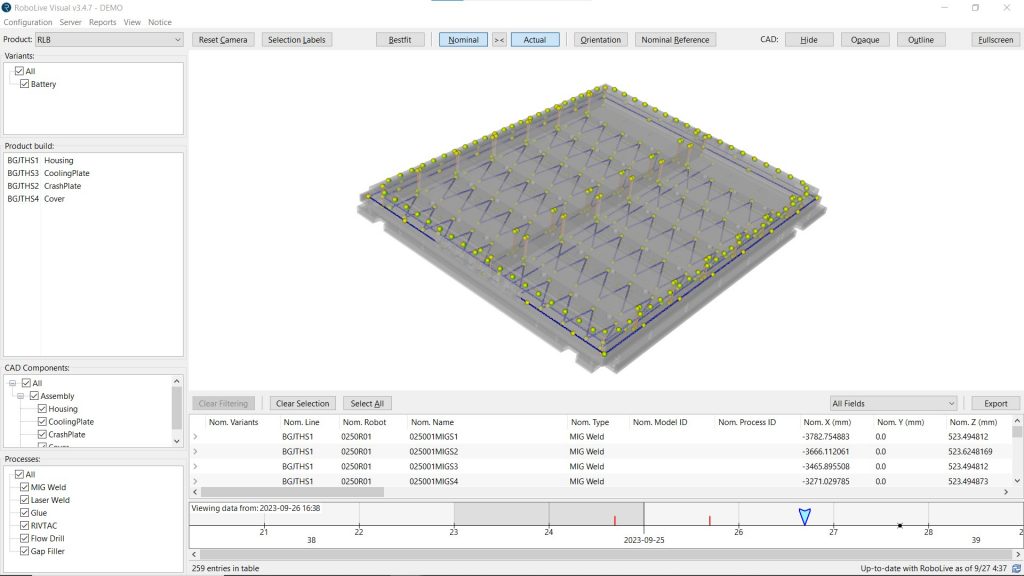

A battery viewed in RoboLive® Visual

That’s not all RoboLive® can do. Battery manufacturing involves sealing, gluing, welding, and drilling—all complex processes involving countless programming instructions. With RoboLive®, you can visualize paths and process parameters on a 3D model of the part, which gives you powerful insight into what your production robots are doing.

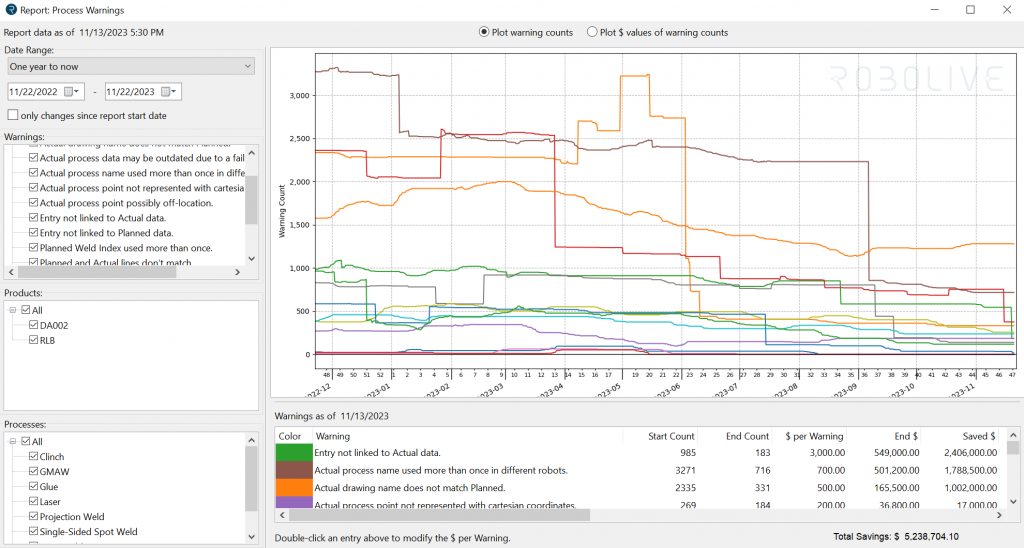

Saving time means saving money, and the benefits RoboLive® brings can add up to over seven figure savings annually on a minimal initial investment. You’ll also see lowered rates of scrap and recall, issues which can have immeasurable costs.

We want you to see for yourself just how powerful RoboLive® is. Right now, we’re offering trial versions of the RoboLive® client software complete with an all-new battery demonstration. You’ll get an up-close look at how RoboLive®’s visualization tools work for battery manufacturers, with

Experience the RoboLive® battery demo today with no obligations by filling out our contact form. If you’d prefer an in-person demonstration of the RoboLive® software solution, you’re in luck: Our team will be appearing next at SOUTHTEC in Greenville SC this October—follow us on LinkedIn for latest updates.