RoboLive® is always improving—it’s how we make good on our mission to deliver cutting-edge software solutions that meet the changing needs of modern manufacturing professionals. Our latest improvement introduces a new feature that will help you understand your factory’s performance over time: the Process Warning Report Dashboard.

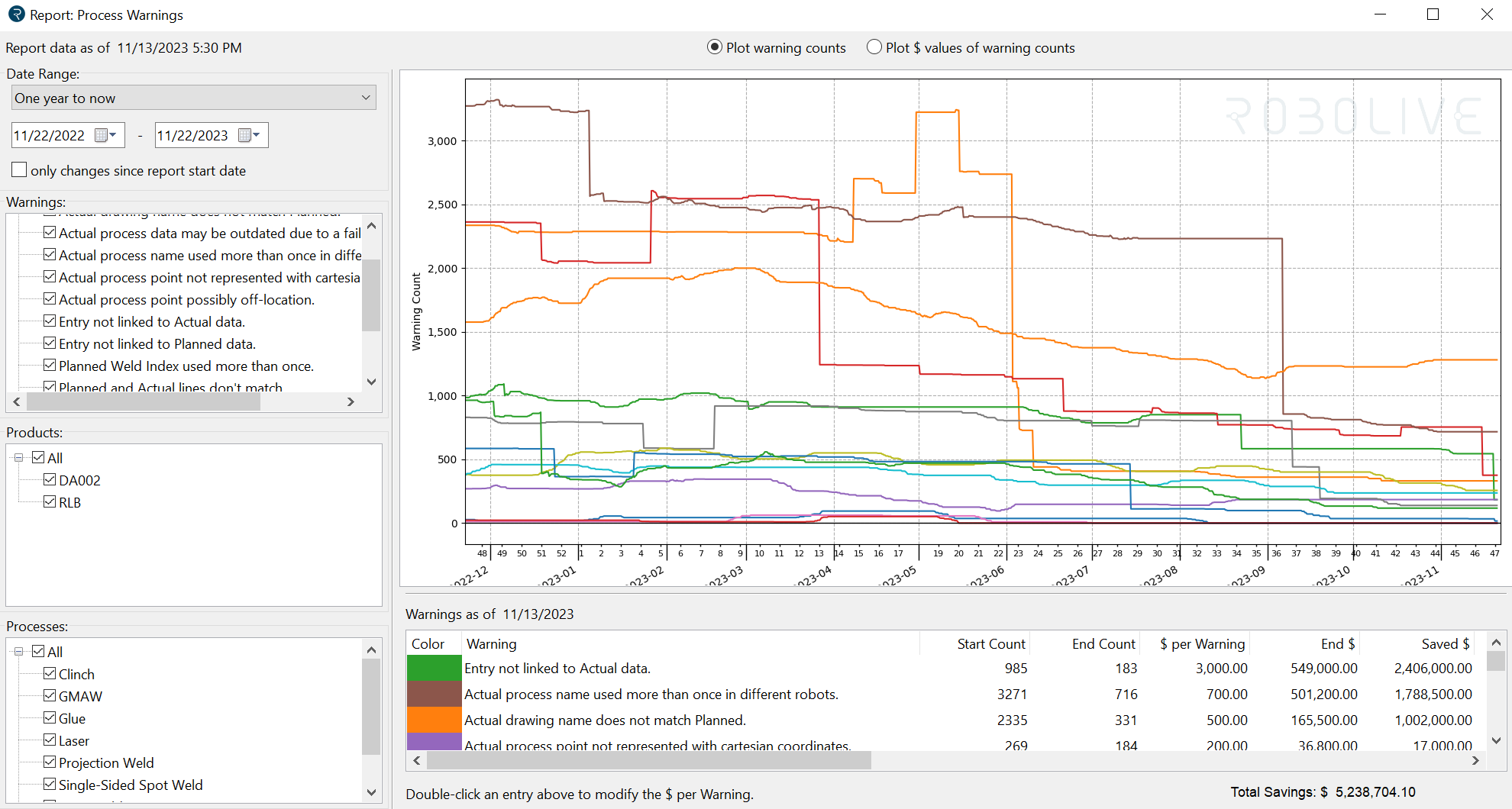

The Process Warning Report Dashboard provides you with several key statistics compiled onto an easy-to-read chart. RoboLive®’s core features track potential issues naturally: problems like deviations from planned data, missing actual data, or off-location processing. The Report Dashboard plots these warnings and their resolutions over time, so you can view and understand maintenance action at a glance. The data is collected at regular intervals and stored over time, meaning you can see day-by-day changes or look for broader trends in how QA issues in your factory are being addressed.

Warnings are associated with specific potential processing issues, and indicate problems that could lead to costly production errors. By associating an estimated cost-per-warning with each issue type flagged, you’ll be able to receive live data about how QA issues affect your bottom line—and how much RoboLive® is saving. The Dashboard is available directly in RoboLive®’s process visualization element, and provides a host of information in a single click:

Every manufacturer knows that time is money. That’s why we created RoboLive®: a powerful set of tools for manufactures using production robots. RoboLive®’s new Report Dashboard feature joins the existing production timeline, along with Process Visualization and four other elements to help you bridge the gap between simulation and reality. RoboLive® is already a proven solution for improving key statistics like OEE, and the Dashboard offers another way to help you visualize and track the metrics that matter most.

RoboLive® was originally developed as an internal solution for engineers from Dressler Automation, an industry leading firm with over 50 years’ experience in manufacturing excellence. Now RoboLive® is being made available to the public for new partners, and clients are already seeing how much RoboLive® can save: Using our full suite of customizable elements, plus tools like the Report Dashboard, major manufactures can expect to see up to seven-figure savings annually. With our flexible pricing, you could see return-on-investment in as little as one year.

If you’re ready to see the Report Dashboard in action, there’s no need to wait. Demo downloads of the latest version of RoboLive are available now. If you’d prefer a guided experience, live demonstrations and custom consultations with a member of the RoboLive team can be scheduled directly via Calendly.

We’re always on our mission to help manufactures produce the best quality products possible, and we’re always improving RoboLive® with features and updates to help you take control of your industrial robots. We have more development planned for RoboLive® in the future, including the potential for bespoke solutions to suit individual manufacturer needs. To keep on top of how RoboLive® is changing the face of industrial automation, follow our LinkedIn page today.