Before the long production process that puts wheels on axles and wipers on windows, cars begin life as a collection of 3D planning documents. While these plans include physical details like lines, curves, and process points, they also includes something you can’t see in real life: the origin point.

The origin point is the arbitrary center of the vehicle from which everything else is referenced. The spots on the vehicle where processes will take place are also referenced from this point. If the origin point (0, 0, 0) is on the hood, for example, then there might be a need to have a spot weld done on the door at (0, 5, 0), relevant to a coordinate system starting at the origin.

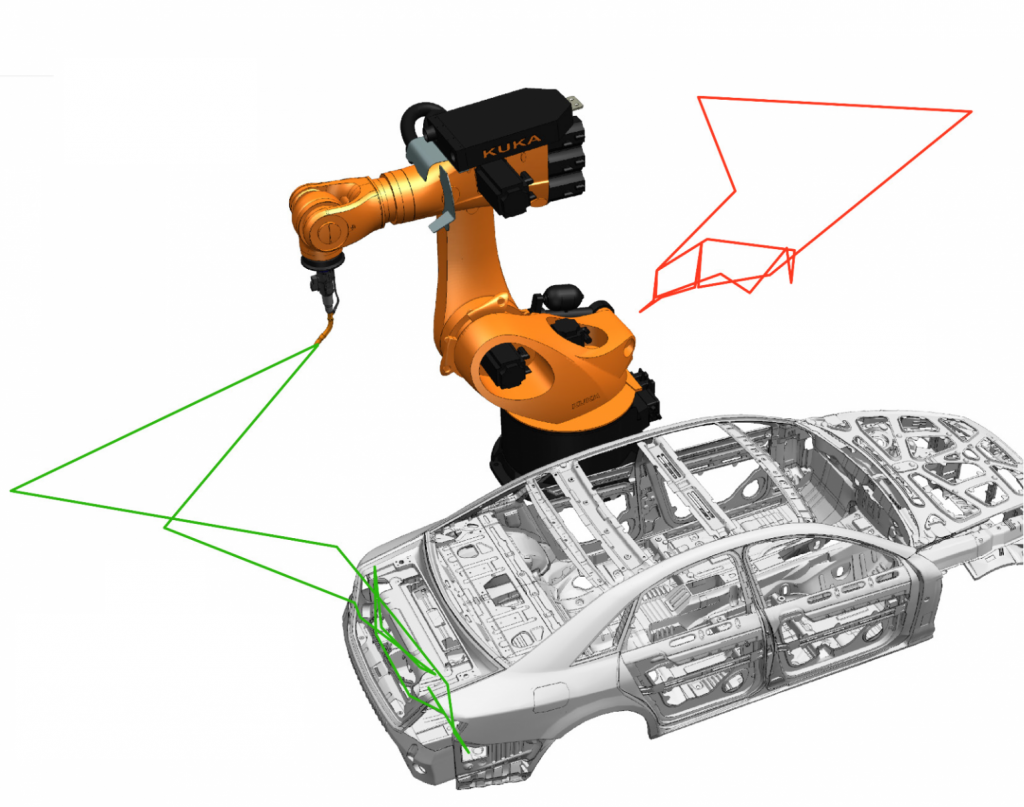

This concept becomes more complicated when robots get involved. Each industrial robot in the production process has its own, separate origins and coordinate systems which are used to calculate their instructions and positioning in 3D space. And during robot programming, it’s these origins—rather than the vehicle’s origin—that are sometimes used as a base. But smart manufacturers are doing things a different way: using vehicle-0 frames instead.

Using vehicle-0 base frames for your robot programs prevents a lot of common problems that occur on the factory floor. This is because unlike other options, vehicle-0 frames reference the part itself—so even if real-world factory conditions differ or diverge from the simulated environment, it’s easy to get things back on track. For example, if a robot is programmed with its own origin as a base frame, any change to the factory means that the part’s position relative to the robot has also changed and instructions based on an expected distance between the two will no longer give the right results. But if your robots are programmed using vehicle-0 base frames, processing instructions are written using the part itself as a reference. That means that no matter how factory conditions change, your program only needs to be re-aligned according to the new position of the part.

For these reasons, vehicle-0 base frames are quickly becoming a standard for manufacturers that mean business. But despite the opportunity for optimization, there are some challenges posed by the implementation of vehicle-0 base frames. For one, it can be difficult to find where exactly the vehicle-0 frame is when re-orienting things or teaching a robot. The origin point isn’t necessarily visible on a part, and may even exist only as abstract points in 3D space. That means that finding the origin point and relaying its location to a robot is a challenging task.

The usual method for finding vehicle-0 base frames involves a process called laser measurement. Using extremely precise measurement tools, specialists find exactly where the vehicle is relative to the robot. From there, calculations can determine where the vehicle’s origin point is located in physical space. When the alignment is complete, processes will be completed in the right place. It solves the problem—but only after an expensive and time consuming process.

Robolive® provides a new path for manufacturers wanting to harness the power of vehicle-0 base frames. Our solution uses the robot itself as a measuring device, so you can reap all the benefits of using the vehicle-0 base frames without the hassle and extra expense of laser measurement. And even if you don’t currently use vehicle-0 base frames as a standard, RoboLive® can be used to update existing robot programs to use them.

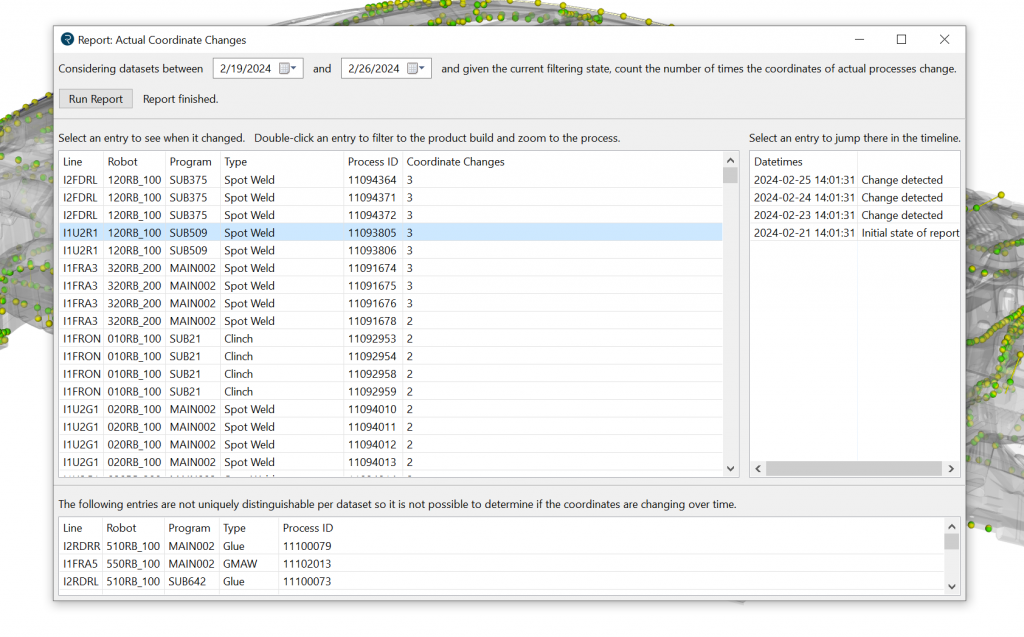

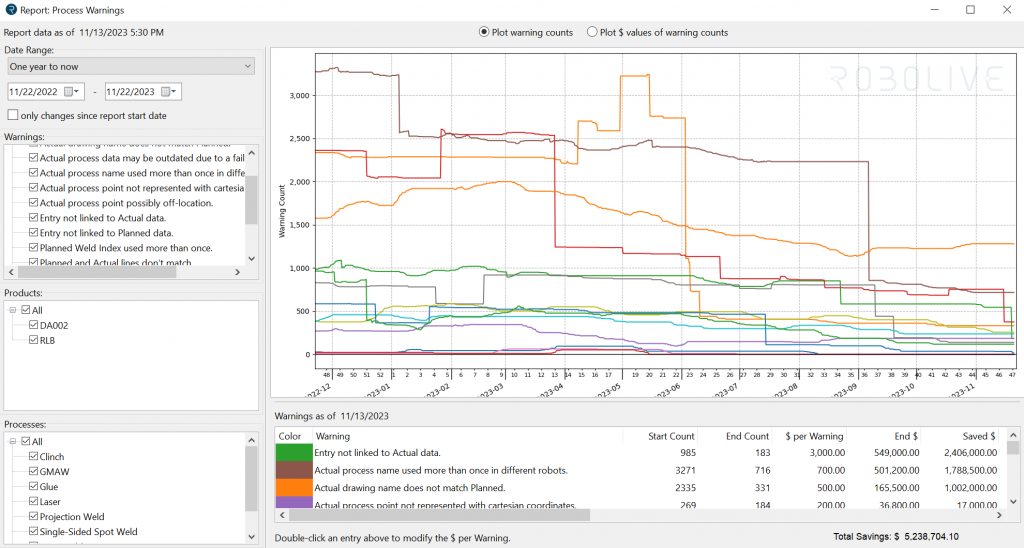

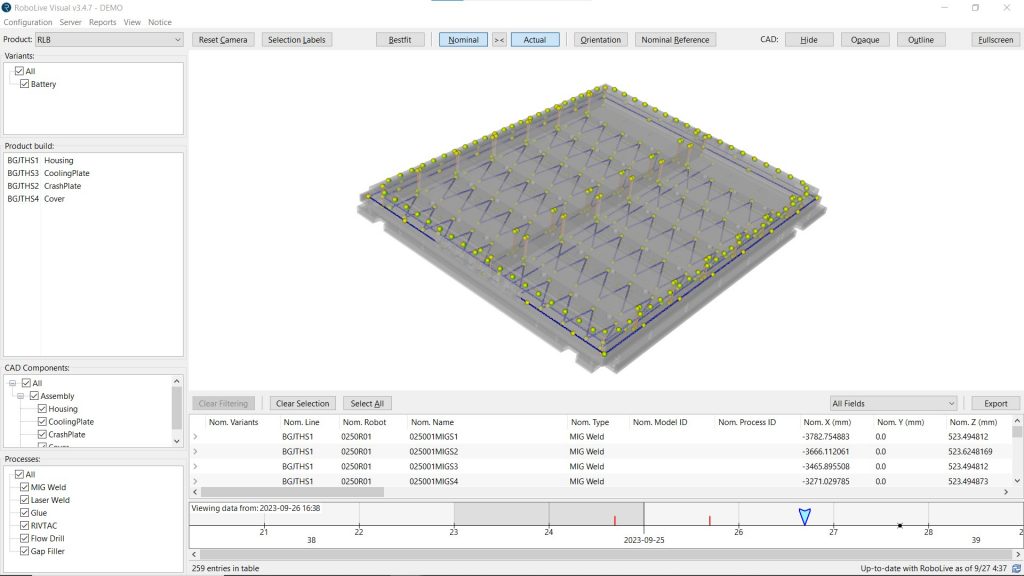

Vehicle-0 frame determination isn’t only way RoboLive® can help you optimize your robotic production processes. Integrated into the local network, the software can automatically retrieves the actual process data from robots, connect it with planned nominal data, and generates insights and understanding of the manufacturing process. With visualization tools, production timelines, and automatic documentation, it’s a one-stop solution that will save time, reduce waste, and improve quality for manufacturing operations of any size.

If you’re ready to take your factory into the modern era, our team is standing by to help. Reach out any time for a free consultation, or get started right away with a demo installation.