From nuts and screws to industrial-strength glues, there are a lot of different processes being performed on a modern assembly line—and a lot of associated production data. But perhaps the most common process, and the one with the most critical data, is robotic welding.

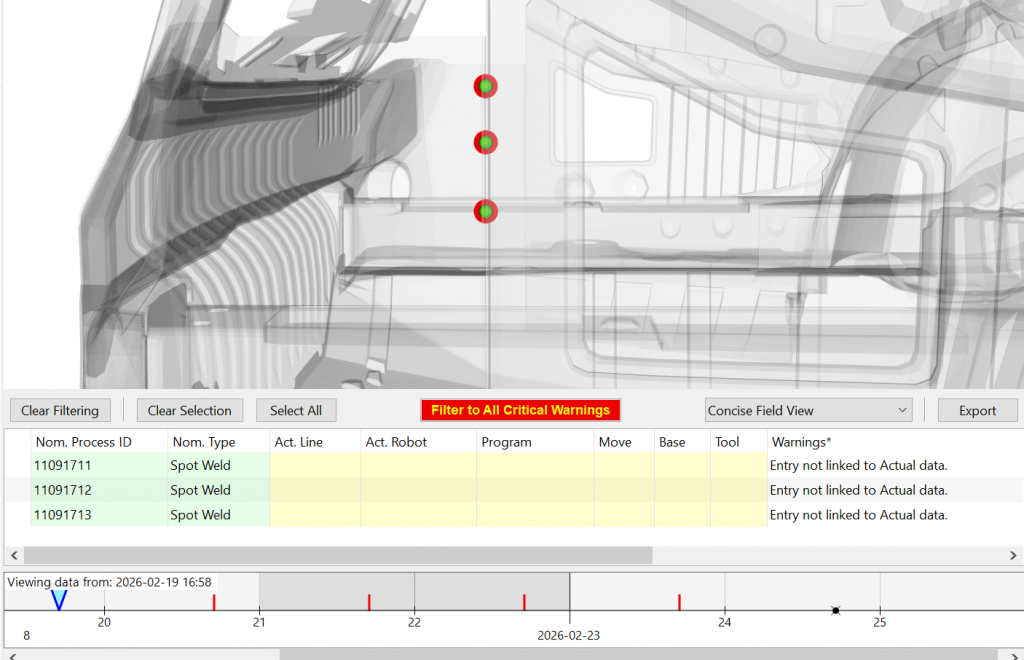

Robotic joining process data refers to specifications about how, where, and when processing like welding is executed, such as XYZ positions or timing. This kind of data comes in an ideal form (the planned processing for a given part or product) and the actual form, which is what the robots are actually programmed to do. Owing to human error during integration, touch-ups, and optimizations cycles, these two sets of data often differ—but both are important to understanding current factory conditions.

While accessing and understanding nominal and actual robotic joining process data can be difficult due to a lack of documentation and obscure sources for information, RoboLive® is a tool that can help. It automatically collects all process data and compiles it into a simple set of visualizations and tables, making it easy to see process positions and associated parameters.

See and Understand Tool Orientation

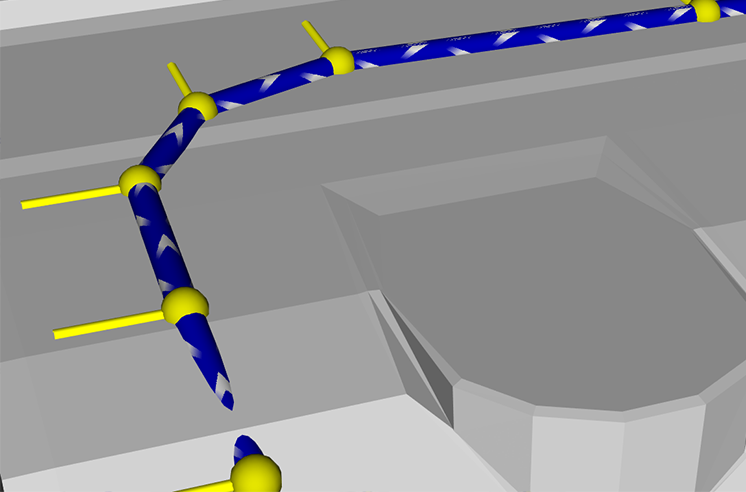

RoboLive® also includes another type of information about each process: the tool orientation. The tool orientation represents the angle of the tool performing the given process, such as a MAG weld or glue seam. For many processes, this information is critical. A spot weld done at even a slightly skewed angle, for example, may not pass current correctly and result in a faulty weld. In some cases, there may even be a risk of damaging the tool or the robot itself if the angle of the process is severely deviated.

The bad welds would be caught later on down the line by quality control interventions like cameras and teardowns, but only after at least some damage has been done. This is because manufacturers without RoboLive® have no real method for proactively addressing this kind of production issue: The data is hard to access and often out-of-date, so it’s not plausible to catch discrepancies in weld angle even during programming audits, and there is typically no system in place to record changes made to this factor in programming touch-ups. Making matters worse is the fact that the tool orientation can also be changed incidentally, as a consequence of unrelated changes to positioning or movement. The deviations that arise in such cases may be minor, but can easily result in bad welds and costly production issues.

RoboLive® is solution created specifically to address these kinds of problems with robotic programming data. We understand that lacking easy access to critical information creates real problems for automotive manufacturers and their suppliers: whether that be the expense of scrap and recall or the challenge of not meeting quality standards. That’s why tool orientation is just one of the many pieces of data included in the RoboLive® Visual Client, where it can be easily seen and understood intuitively with a glance at any PC.

By toggling the tool origination button in the RoboLive® Visual Client, a column will appear in the visualization window indicating the angle and direction of each process point. Because the data is sourced directly from your robots and production plans, the client is a source for all information related to process orientations, potentially including nominal/actual comparisons or a numeric representation in the parameter table.

RoboLive® is more than just a centralized source for up-to-date programming data. The software autonomously records new programming changes as often as every shift, so it can also serve as a complete record of any update made to any robot’s programming instructions. In the case of tool orientation, just a simple click on the timeline can reveal any changes to the angle. And if necessary, custom errors can warn you if a weld angle is too far from specifications.

Having access to this information can solve a lot of problems, and prevent a lot more. An error warning in RoboLive® can easily alert staff to a weld programmed at an angle that would result in an issue, far earlier than a vision system or teardown ever could. No matter how they’re spotted, all production errors come with an instant RCA, because RoboLive will also show you all information about where the problem took place and when it was introduced. For component manufacturers, RoboLive® is a well-recognized tool that can be used to prove quality programming to clients.

It's more than just process visualization

Process orientation visualization is just one of the many ways RoboLive® can change the way you interact with you robotic joining process data. The software solution works completely autonomously to turn your robot backups and production plans into a single source of truth for all programming data, complete with quality auditing tools and analyses. To try RoboLive® for yourself via a free demonstration, or to schedule a consultation with our engineers, sign up today.