Worry-free installation.

Effortless results.

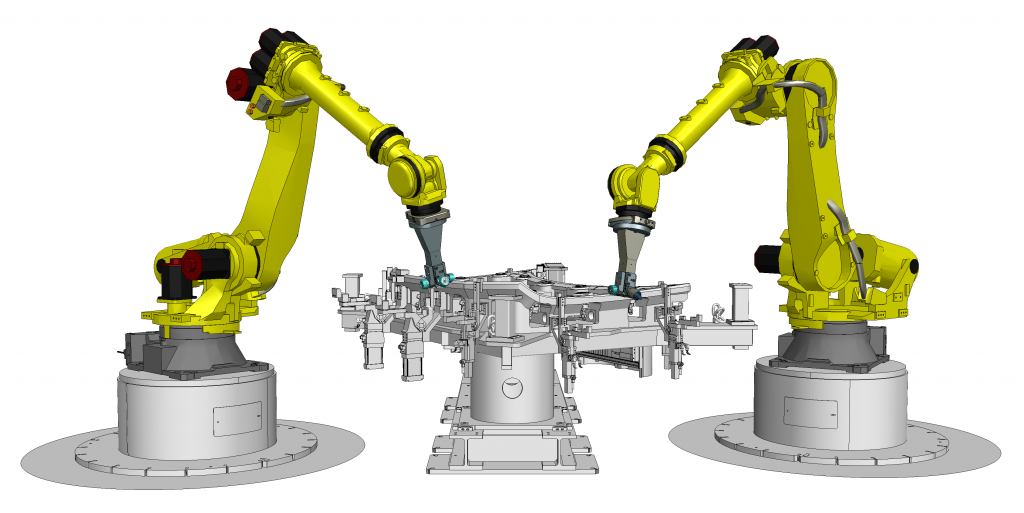

RoboLive® gathers data from your industrial robots, processes it, and automatically distributes the results to a visual client installable on any PC in the plant. It’s a completely hands-free way to store and analyze robotic process data.

-

NO TRANSITION COSTS OR DISRUPTIONSYou don’t need to stop production to install or use RoboLive®. It works alongside existing systems and is intuitive enough to use without training.

-

MINIMAL INITIAL INVESTMENTInitial setup of RoboLive® is available at a low cost, with feasibility studies available to prove the concept. The system can be upgraded with new features at any time.

-

ONE-TIME PRICING, LIFETIME ACCESSTransparent and flexible pricing plans make it easy to budget for RoboLive® in the long and short term.

Don't settle for status quo.

Spreadsheets or outdated manual toolkits leave room for improvement. Handling robot data takes hours of expensive specialist work: quality checks, programming correction, and more. Hard-to-solve problems lead to expensive downtime. And reliance on reactive QA strategies

RoboLive® will change the way you hand robotic processing data. The easy-to-use system lets all staff interact with data in a natural environment either in the office or on the production floor. It instantly detects root causes with regular automatic analysis of robot backups while providing a single, accessible source of truth for critical production information like weld parameters or positions.

get real results, fast.

As a new solution to a common set of challenges, RoboLive® is rapidly being adopted as the industry-standard for organizations looking to develop digitalization or Industry 4.0 initiatives.

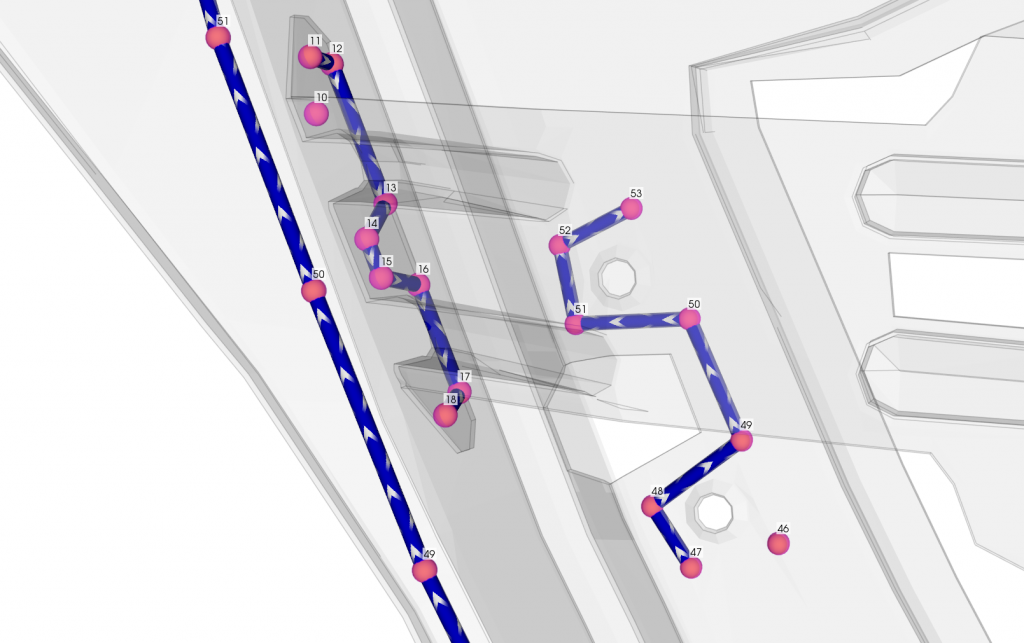

The RoboLive® Visual Client is installable on any Windows PC, and combines your planned data, product models, and regular updates of real robot data into a simple visual format with analysis and error detection.

While the exact benefits of a new software tool can be difficult to quantify, RoboLive® users see immediate measurable improvement to key performance indicators.

a solution for any business objective:

MTTR

UPTIME

The length of & need for production stops is reduced with a clear source for robotic processing data.

defect rate

Custom errors & warnings will detect programming problems before production begins.

oee

tqm/tqc

Empower all staff to participate in quality initiatives with easy-to-understand, democratized weld & glue data.

Verification

Validate commissioning work at a glance, or monitor the status of lines in progress with visual tools.

Downtime reduction

Scrap Prevention

Wage cost control

SUCCESS STORIES

RoboLive® is used every day by major manufacturers of all sizes. Read on for stories of how OEMs, suppliers, and more have found success with our software.